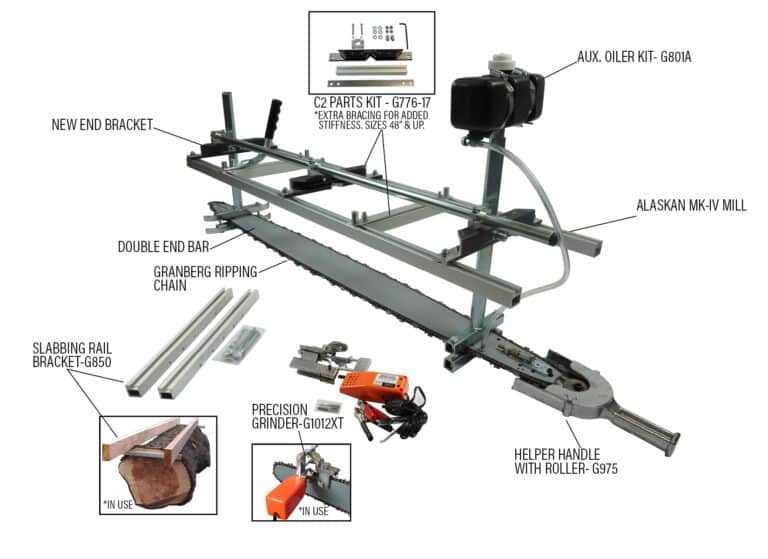

ALASKAN® MKIV CHAINSAW MILL C2-C3 PACKAGES

Not Sure Which Product is Right for You?

Frequently Asked Questions

What makes Granberg Alaskan® chainsaw mills special?

Granberg International produces 100% American-made chainsaw mills known for high-quality construction and durability. Our mills are manufactured in the USA with premium materials, offering precision engineering that converts your chainsaw into a portable lumber-making tool ideal for creating slabs and beams where traditional sawmills aren’t accessible.

How do I set up my new Alaskan® saw mill?

Setting up your Alaskan® mill is straightforward. Attach the mill’s brackets to your chainsaw bar, secure them with the provided bolts, and adjust the guide rails to your desired slab thickness. For best results on your first cut, use a level guide board attached to the log. We recommend watching our setup video before your first milling session.

Which chainsaws work best with Granberg mills?

Our Alaskan® mills are compatible with most popular chainsaw models. For effective milling, we recommend powerful saws like the Stihl MS661 or MS880, particularly for processing larger diameter logs into thick slabs. The right chainsaw bar length depends on the width of logs you’ll be milling.

What's special about the Alaskan® MKIV chainsaw mill?

The Alaskan® MKIV is our professional-grade model featuring enhanced precision adjustments for consistent, accurate cuts. Its robust design handles demanding milling processes with ease, allowing woodworkers and forestry professionals to create dimensional lumber with repeatable accuracy from logs of various sizes.

What's the secret to successful lumber milling?

Successful milling is really about patience and proper equipment. Use a sharp ripping chain designed specifically for the milling process. Move at a consistent pace, letting the saw do the work. Apply steady pressure and maintain proper adjustments for the thickness you desire. With Granberg equipment, you’ll achieve professional-grade results whether creating boards, beams, or slabs.

Be the first to know

- Early Access to New Products

- First to know about Promotions

- Fun Tips and Tricks